Nett Technologies’ GreenTRAP™ VOLT-Series is a passive / active Diesel Particulate Filter (DPF) system designed to remove particulate matter from medium to heavy duty diesel engines in stationary applications. Utilizing a proprietary catalyst and a set of electrical heaters, the GreenTRAP™ VOLT-Series can automatically perform self-cleaning (regeneration) without relying on engine exhaust temperature and is truly an effective solution to your particulate matter challenges.

Home Page Products Diesel Particulate Filters (DPF) GreenTRAP™ VOLT-Series (Active DPF)

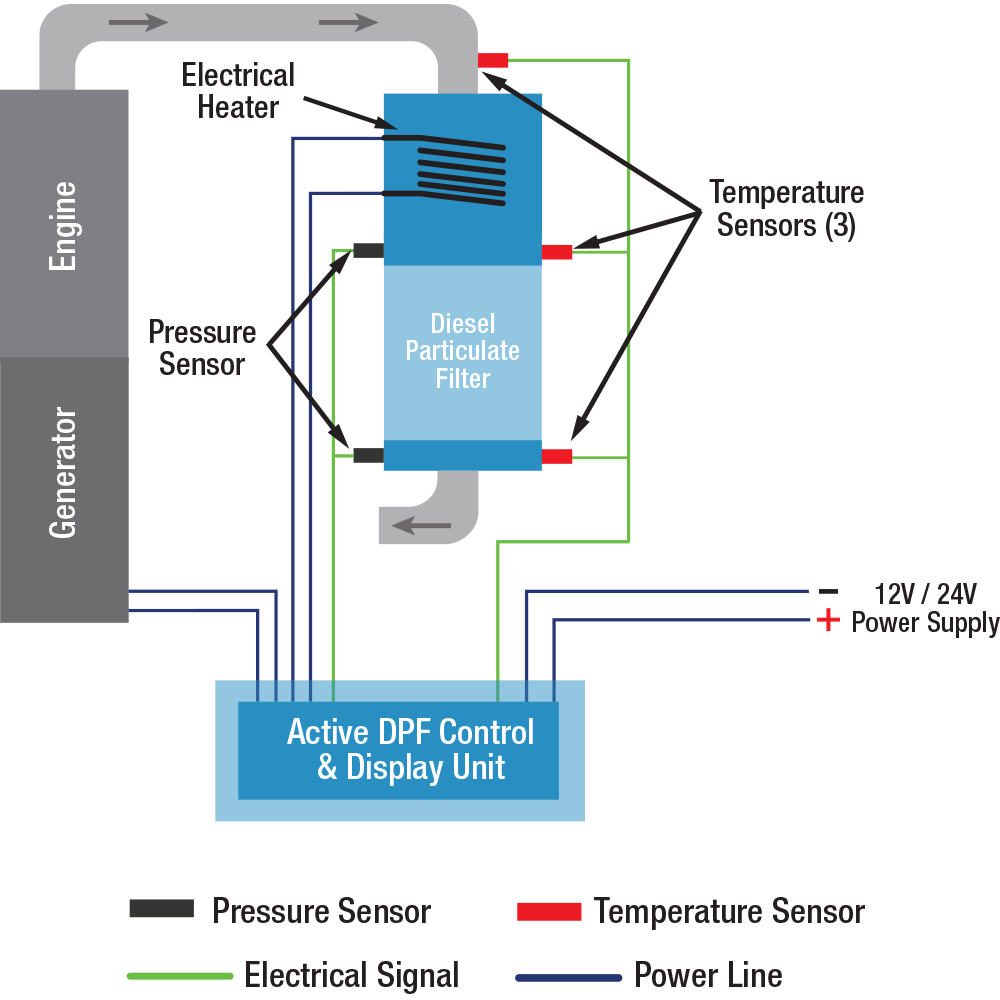

The GreenTRAP™ VOLT-Series is an active Particulate Matter (PM) control system that consists of a Diesel Particulate Filter (DPF) integrated with a set of electrical heaters and can automatically perform self-cleaning (regeneration) without relying on engine exhaust temperature. It is designed to control emissions of PM from medium and heavy-duty diesel engines in stationary applications. The GreenTRAP™ VOLT-Serie system uses a proprietary catalyst on the inner surfaces of the filter walls which reduces the regeneration temperature and therefore allows the system to passively regenerate in favorable engine exhaust operating temperatures leading to a less frequent active regeneration requirement. When a temperature is not sufficient for passive regeneration, a set of electric heater coils are used to increase the exhaust temperature for active regeneration. An Electronic Control Unit (ECU) evaluates the system parameters such as temperature, pressure and exhaust mass flow rate in real time and uses these values to predict and activate the regeneration cycle.

The GreenTRAP™ VOLT-Series ECU continuously monitors and measures the performance of all system sensors and components. In the event of a malfunction, the ECU will indicate the existence of a problem to the operator via the system display.

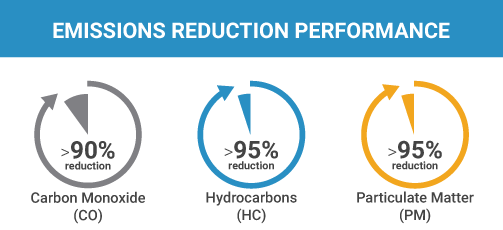

The GreenTRAP™ VOLT-Series system can reduce 95-99% PM out of the engine exhaust. In addition, the system provides a reduction in Carbon Monoxide (CO) and Hydrocarbons (HC) emissions greater than 90% and 95% respectively.

Nett Technologies’ GreenTRAP™ VOLT-Series is a passive/active Diesel Particulate Filter (DPF) system which is designed to control emissions of Particulate Matter (PM) from medium and heavy-duty diesel engines in stationary applications. The system contains a set of electric heater coils that are used to increase the temperature of the exhaust for active regeneration allowing the system to run without relying on engine exhaust temperature. The wall-flow Diesel Particulate Filter (DPF) traps Particulate Matter (PM) emissions emitted by the diesel engines. The cylindrical filter element of the device consists of many square parallel channels running in the axial direction, separated by thin porous walls. A proprietary catalyst is wash-coated on the inner surfaces of the monolith channels. The catalyst lowers the Particulate Matter (PM) oxidation temperature allowing a filter to passively regenerate at lower temperatures. When the exhaust temperature is not sufficient for passive regeneration, an active regeneration will be automatically triggered. During active regeneration, the electrical control unit utilizes excess power from your generator in a controlled manner to increase the exhaust temperature to levels that can safely oxidize collected soot in the Diesel Particulate Filter (DPF).

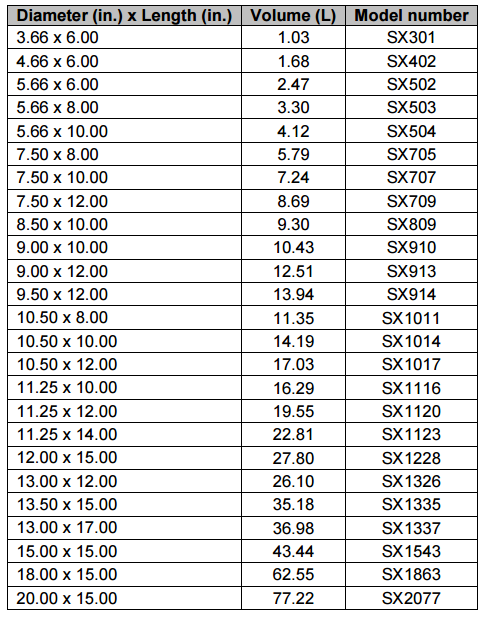

Standard models of GreenTRAP™ VOLT-Series Diesel Particulate Filters (DPF) are listed below. Filter sizing guidelines in the table are approximate. Sizing for particular engines and applications should be consulted with our office before ordering.

DPF Sizes and Model Numbers

The GreenTRAP™ VOLT-Series is an active Particulate Matter (PM) control system that consists of a Diesel Particulate Filter (DPF) integrated with a set of electrical heaters and can automatically perform self-cleaning (regeneration) without relying on engine exhaust temperature. It is designed to control emissions of PM from medium and heavy-duty diesel engines in stationary applications. The GreenTRAP™ VOLT-Serie system uses a proprietary catalyst on the inner surfaces of the filter walls which reduces the regeneration temperature and therefore allows the system to passively regenerate in favorable engine exhaust operating temperatures leading to a less frequent active regeneration requirement. When a temperature is not sufficient for passive regeneration, a set of electric heater coils are used to increase the exhaust temperature for active regeneration. An Electronic Control Unit (ECU) evaluates the system parameters such as temperature, pressure and exhaust mass flow rate in real time and uses these values to predict and activate the regeneration cycle.

The GreenTRAP™ VOLT-Series ECU continuously monitors and measures the performance of all system sensors and components. In the event of a malfunction, the ECU will indicate the existence of a problem to the operator via the system display.

The GreenTRAP™ VOLT-Series system can reduce 95-99% PM out of the engine exhaust. In addition, the system provides a reduction in Carbon Monoxide (CO) and Hydrocarbons (HC) emissions greater than 90% and 95% respectively.

Nett Technologies’ GreenTRAP™ VOLT-Series is a passive/active Diesel Particulate Filter (DPF) system which is designed to control emissions of Particulate Matter (PM) from medium and heavy-duty diesel engines in stationary applications. The system contains a set of electric heater coils that are used to increase the temperature of the exhaust for active regeneration allowing the system to run without relying on engine exhaust temperature. The wall-flow Diesel Particulate Filter (DPF) traps Particulate Matter (PM) emissions emitted by the diesel engines. The cylindrical filter element of the device consists of many square parallel channels running in the axial direction, separated by thin porous walls. A proprietary catalyst is wash-coated on the inner surfaces of the monolith channels. The catalyst lowers the Particulate Matter (PM) oxidation temperature allowing a filter to passively regenerate at lower temperatures. When the exhaust temperature is not sufficient for passive regeneration, an active regeneration will be automatically triggered. During active regeneration, the electrical control unit utilizes excess power from your generator in a controlled manner to increase the exhaust temperature to levels that can safely oxidize collected soot in the Diesel Particulate Filter (DPF).

Standard models of GreenTRAP™ VOLT-Series Diesel Particulate Filters (DPF) are listed below. Filter sizing guidelines in the table are approximate. Sizing for particular engines and applications should be consulted with our office before ordering.

DPF Sizes and Model Numbers